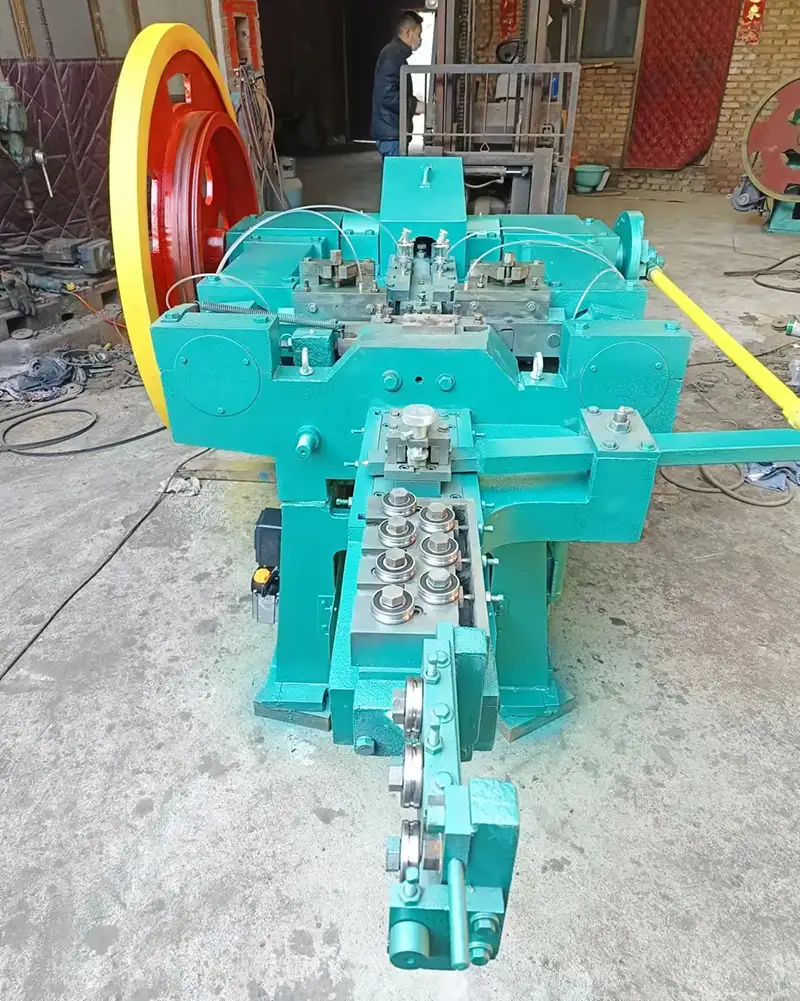

Automatic High Quality Steel Nail Making Machine

Introduction to Fully Automatic Nail Making Machine

Overview:

A fully automatic nail making machine is a high-precision, efficient, and versatile piece of equipment designed to produce nails of various sizes and types. This machinery is widely used in the construction, furniture, and packaging industries, where there is a constant demand for high-quality nails. The fully automatic nature of these machines ensures consistent production, reduces labor costs, and enhances overall productivity.

Key Features:

1. High Automation:

- The machine operates with minimal human intervention, from raw material feeding to the final product output.

- It includes automated systems for wire feeding, cutting, forming, and sorting.

2. Versatility:

- Capable of producing a wide range of nail types, including common nails, roofing nails, concrete nails, and more.

- Adjustable settings allow for the production of nails of different lengths, diameters, and head shapes.

3. Precision and Quality:

- Equipped with advanced sensors and control systems to ensure high precision and uniformity in nail dimensions.

- Consistent quality is maintained through precise control over the entire manufacturing process.

4. High Production Capacity:

- Designed to handle large volumes of production, capable of producing thousands of nails per hour.

- Continuous operation with minimal downtime, ensuring maximum efficiency.

5. User-Friendly Interface:

- Easy-to-use control panel with intuitive interfaces for setting parameters, monitoring production, and troubleshooting.

- Real-time data display and diagnostic features for quick adjustments and maintenance.

6. Safety Features:

- Built-in safety mechanisms, such as emergency stop buttons, protective guards, and sensor-based shutdowns, to ensure operator safety.

- Compliance with international safety standards and regulations.

7. Energy Efficiency:

- Energy-efficient design with optimized power consumption, reducing operational costs.

- Some models include energy-saving features such as automatic power-off during idle periods.

8. Durability and Reliability:

- Constructed with high-quality materials and robust components to withstand the rigors of continuous operation.

- Regular maintenance and service support ensure long-term reliability and performance.

Applications:

- Construction Industry: For the production of nails used in building, framing, and roofing.

- Furniture Manufacturing: For the assembly of wooden furniture and cabinetry.

- Packaging Industry: For the production of nails used in crate and pallet construction.

- DIY and Home Improvement: For smaller-scale nail production for DIY projects and home repairs.

Conclusion:

A fully automatic nail making machine is an essential tool for manufacturers looking to produce high-quality nails efficiently and cost-effectively. With its advanced automation, versatility, and precision, this machine can significantly enhance production capabilities while reducing labor costs and improving product consistency. Whether for large-scale industrial use or smaller custom applications, a fully automatic nail making machine is a valuable investment for any business in the nail manufacturing sector.

Previous Products:None

Next Products:gabion machinery